Field service scheduling

Optimize the schedule of your engineers via a visual and easy-to-use service scheduling software

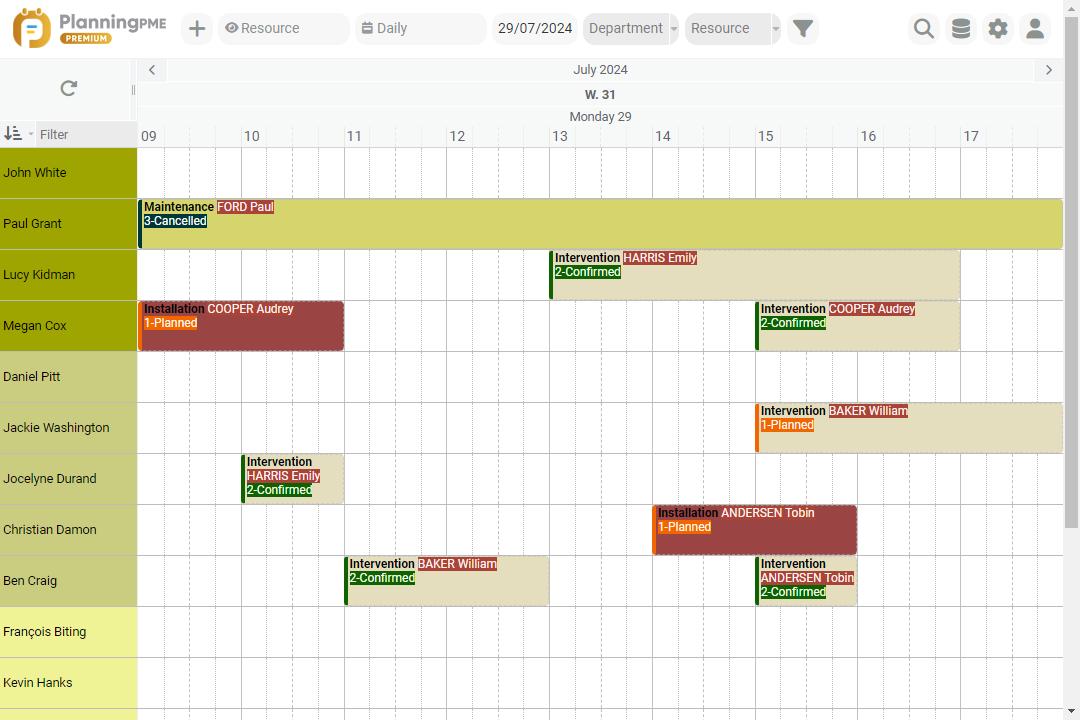

Effective management of planned interventions and recurring interventions is essential for any service company. With scheduling software, activity managers can ensure preventive maintenance and adherence to deadlines while optimizing the working time of maintenance technicians, inspectors, auditors, and drivers. The software interface provides an overview of field interventions, facilitating the assignment of tasks to appropriate worker. Client notifications, such as service notices and time slots, enhance communication and customer satisfaction.

Improve your technicians schedule management

Alerts and notifications

Reports and statistics

Customer management

Scheduling solutions to manage your service interventions

For a service company, managing scheduled interventions such as troubleshooting, repair, maintenance, and servicing is optimized through a well-coordinated team. Using a scheduling software allows you to track each appointment and manage the nature of the intervention in a centralized manner. Maintenance technicians and other service providers can access an overview of their tasks from the dashboard, ensuring rapid and effective intervention. This reduces wait times for customers and optimises the available resources.

Simplify the management of interventions for your technicians with the online shared schedule. A few clicks are enough to create a new work order or assign it to another skilled and available engineer. Optimize your employees' workload and quickly organize last-minute field services. Also, manage all types of vehicles and check their availability in real time.

Manage the scheduling process from the beginning to the end

Whatever your activity sector (electricity, air conditioning, telecommunication, conveyor…) and the intervention type that you have to fulfill ( after-sales service, maintenance, delivery…) you need a field service management tool.

With PlanningPME you can optimize your event management, vehicle fleet and technicians schedule. Shift schedule, maintenance events, recurrent tasks or again urgent repair needs are managed efficiently.You can manage the schedule of your mobile teams ( delivery man, installer, sales force, technicians…).

Thanks to e-mail alerts and notifications, technicians are warned with any change in the schedule and risks are managed in real-time. Whenever you need to manage the schedule of employees, check the availability of a technician or assign him to a mission according to his skills, PlanningPME allows you to manage your activity with a few clicks. Shared schedule and user rights management give your collaborators access to their calendar at any time.

They trust us

We are a company that is very active in the technical maintenance of HVA (Heating / Ventilation / Air-conditioning) systems. We were looking for a scheduling system that was simple to implement and use. We tested two, including yours, and immediately chose PlanningPME. Our choice was very easy because your site is very well constructed and after downloading the trial version, the choice was made.

Swis Clima SA

Challenge Bat

Mitutoyo

Jaquet SA

A&C Sistemi

FAQ

To draw up a work schedule, start by defining the objectives, identifying the tasks to be carried out and assessing the human and material resources required. Next, organize these tasks in a logical order, taking into account priorities and dependencies, and setting clear deadlines for each task. Finally, make sure you communicate the schedule to all the parties involved, and monitor it regularly to adjust in the event of unforeseen circumstances.

Here is how to create a preventive maintenance schedule in 7 steps:

- Identify the equipment to be maintained : List all critical equipments requiring regular maintenance.

- Define maintenance tasks : Establish the specific interventions to be carried out for each piece of equipment, such as cleaning, greasing, or safety checks.

- Determine the maintenance frequency : Set time intervals (daily, weekly, monthly, etc.) based on manufacturers' recommendations and operational experience.

- Allocate the necessary resources : Assign the qualified personnel and the required tools for each maintenance task.

- Create the maintenance schedule : Schedule services on a calendar taking into account production constraints and resource availability.

- Document and track services : Record each task performed to track the history of services and facilitate future audits or analyses.

- Review and adjust the schedule regularly : Update the schedule based on feedback, new priorities, or equipment changes.

30-day free trial to boost your schedule management

Request a demo Free trial